Getting Started | Envirotherm Cabinets

Intended Use, Safety Guidelines, and Environmental Considerations

Applicable Models:

| TEC-460-SD TEC-850-SD |

📜 Quick Navigation

|

|

Intended Use

The Thermoline Envirotherm temperature and humidity cabinets, available in 460L and 850L models, are designed and manufactured to provide precise temperature and humidity control. These cabinets are ideal for testing samples under various temperature and humidity conditions, often while under electrical load.

Operating within a range of -35°C to +120°C with adjustable alarms, Thermoline temperature and humidity cabinets set the industry standard for reliable environmental control.

- Thermoline Envirotherm cabinets come only in a solid door option.

- TEC cabinets operate within a temperature range of -35°C to +120°C, with a maximum humidity level of 95%.

Uncrating/Unpacking

Unpacking process for foam wrapped and crated:

- The Envirotherm cabinet will be delivered foam-wrapped and on its castors via sensitive freight (Fig 1) or in a crate.

- If the cabinet is delivered on a crate, remove the packaging by unscrewing both the left and right sides. A forklift may be required to lift the cabinet off the crate safely.

- Please only dispose of the packaging once the Envirotherm cabinet is inspected. If any damage is found, contact your supplier or Thermoline immediately at:

Moving

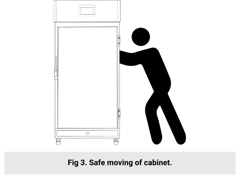

Moving the Envirotherm cabinet:

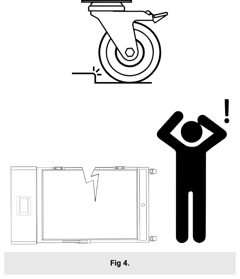

- Ensure that the Envirotherm cabinet is rolled on an even and flat surface. Uneven surfaces can cause the cabinet to fall over.

IMPORTANT

Envirotherm cabinets are 'Top Heavy'. Do not move the cabinet too quickly. (Fig 3 & 4)

Operating Environment

Cabinet Location

- Place the cabinet away from direct sunlight and heat sources (e.g., heaters).

- Ensure the room's ambient temperature does not exceed the cabinet's operational limits.

- The Envirotherm cabinet should be stored inside at all times. Failure to adhere to this could cause significant drops in cabinet performance and damage to items stored inside.

- If multiple cabinets are placed close together, heat buildup can occur due to airflow direction. One cabinet may transfer heat to the next, affecting performance. To prevent this, ensure cabinets are spaced more than 300mm apart or positioned so that hot air is not directed into adjacent units.

Environmental Conditions

| Condition | Temperature | Humidity |

| Extreme Operating Environment | 10°C to 32°C | Up to 85% RH |

| Optimal Environment | 23°C (±2.0°C) | 50% RH (±5% RH) |

Electrical Connections

All Envirotherm cabinets require a 15amp, 230V, 50Hz power supply. Use a dedicated outlet for the cabinet, and avoid using power boards or extension cords. Each cabinet is supplied with a standard 3-pin moulded plug for connection to the mains.

All Envirotherm cabinets require a 15amp, 230V, 50Hz power supply. Use a dedicated outlet for the cabinet, and avoid using power boards or extension cords. Each cabinet is supplied with a standard 3-pin moulded plug for connection to the mains.

Power Supply:

-

All Envirotherm cabinets come with a 2.5m removable mains power lead, featuring a three-pin plug and a female IEC plug. Ensure the cabinet is positioned at a reasonable distance from the power supply.

-

The cabinet itself has a male IEC socket.

Water Quality

For optimal performance, follow the recommended water quality parameters below. Due to the extensive use of stainless steel in Thermoline products, do not use deionised water. It can cause corrosion (due to leaching over time) that may not be covered under warranty.

| Parameter | Range |

| Resistivity | 0.1 - 0.5 MΩ |

| Conductivity | 2-10 µs/cm |

| Total Dissolved Solids | <10 mg/L |

| Acidity | 6-7 pH |

Avoid tap water if possible. Using tap water may significantly increase the required frequency of cleaning and maintenance of the equipment. Unacceptable water can cause excess scale build-up and mineral deposits, particularly in humidity systems. This, in turn, can cause heater failure and issues with oat switches. In water baths, corrosion due to insucient cleaning is the primary concern, with heater circulators and circulation pumps being the most signicant issue.

Note: All Thermoline equipment using water requires regular maintenance, inspection and cleaning. Six monthly for Humiditherm, Envirotherm and Climatron cabinets. Water baths will require much more frequent cleaning due to the ease of contamination in the water. Water should be changed for any signs of contamination.

WARNINGS

WARNINGS

- Envirotherm cabinets require adequate ventilation, with at least 300mm of clearance on either side and at the back. If multiple TEC or TRH cabinets are placed close together, additional spacing may be necessary to ensure proper airflow. See also TEC/TRH Deflector.

- Envirotherm cabinets should be stored inside at all times. Failure to adhere to this could cause significant drops in cabinet performance and damage to items stored inside.

- Ensure that the feed water is suitable for the cabinet.

- Envirotherm cabinets are not suitable for use with flammable solvents! They are fitted with components that may be the source of ignition.