Getting Started | Platelet Shaker

Intended Use, Safety Guidelines, and Environmental Considerations

Applicable Models:

| TPS-18 |

📜 Quick Navigation

Intended Use

The Thermoline TPS-18 Platelet Shaker is designed for the controlled agitation of platelets.

Features:

- Robust geared motor with fixed speed control (60 rpm).

- Removable slide-out trays for easy access, accommodating up to 18 large platelet bags.

- Suitable for freestanding benchtop use or integration with the Thermoline TMLR-200 refrigerated incubator.

Unpacking

Unpacking Process for Box and Skid

- The platelet shaker is securely packed on a timber skid with a lift-off carton placed over the top, then strapped to the skid for transport.

- Before proceeding, ensure that all internal (if present) and external packaging materials, including tape, plastic bags, and foam pieces, have been removed.

- To unpack, first cut the straps securing the carton to the skid, then carefully lift the carton upwards to remove it.

- If any damage is found upon opening, report it immediately to your supplier or Thermoline at +61 2 9604 3911 or service@thermoline.com.au

Moving

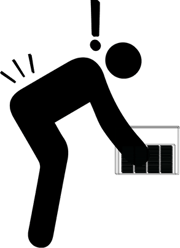

- Take caution when moving and positioning the platelet shaker due to its weight. The TPS-18 model weighs approximately 29 kg.

- Ensure proper lifting techniques and, if necessary, use assistance to prevent injury or damage.

Operating Environment

Shaker Location

- Place the shaker away from direct sunlight and heat sources (e.g., heaters).

- Ensure the room's ambient temperature does not exceed the shaker's operational limits.

- Shakers should be stored inside at all times.

- Ensure that the platelet shaker is kept away from water. Leave space around the base for ventilation to allow proper airflow.

- A circulating fan in the base removes heat generated by the geared motor—ensure that the ventilation slots are not blocked to maintain optimal performance.

Environmental Conditions

| Condition | Temperature | Humidity |

| Extreme Operating Environment | 10°C to 32°C | Up to 85% RH |

| Optimal Environment | 23°C (±5°C) | 50% RH (±25% RH) |

Electrical Connections

- The shaker requires a 10Amp, 230V, 50Hz power supply.

- A dedicated outlet should be used for the platelet shaker. Do not use power boards or similar devices.

- The platelet shaker can also be plugged into a TMLR-200 when used in the incubator.

- The platelet shaker includes a 2.5m removable mains power lead with a three-pin plug and a right-angle female IEC plug.

- Ensure the unit is positioned at a reasonable distance from the power supply for safe operation.

- On the platelet shaker, there is a 10Amp male IEC socket (power port). Ensure that both the mains plug and the switch are easily accessible.

Operating Environment Warnings

Operating Environment Warnings

- Never block the air vents on the platelet shaker. This can cause damage due to excessive heat buildup.

-

The platelet shaker requires an even surface to ensure consistent performance. Internal contents may be damaged if the shaker is placed on an uneven surface.

-

The platelet shaker should be stored inside at all times. Failure to do so may cause significant drops in performance and potential damage to stored items.

-

The platelet shaker is not suitable for use with flammable solvents. It is fitted with components that may be a source of ignition.