Getting Started | Glassware Drying Ovens

Intended Use, Safety Guidelines, and Environmental Considerations

Applicable Models:

| TGD-80F TGD-150F TGD-250F |

|

📜 Quick Navigation

🔍 Need More Information?

📦 Setup & Installation

⚙️ Operating Procedures

🧰 Maintenance & Cleaning

🔧 Troubleshooting & Repair

📜 Warranty & Support

Intended Use

The Thermoline glassware drying ovens 80F, 150F, and 250F models are designed and manufactured to dry glasswares, operating at ambient +10°C to 80°C.

Uncrating/Unpacking

Unpacking process for foam wrapped and crated:

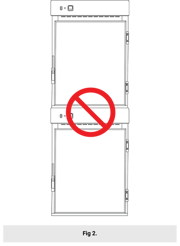

The drying oven will be delivered foam wrapped and on its castors via sensitive freight (Fig 1) or in a box on a skid (Fig 2).

The drying oven will be delivered foam wrapped and on its castors via sensitive freight (Fig 1) or in a box on a skid (Fig 2).- If the drying oven is delivered on a skid, a forklift may be required to lift it off the skid.

- Please only dispose of the packaging once the the oven is inspected. If any damage is found, contact your supplier or Thermoline immediately at:

- Phone: +61 2 9604 3911

- Email: service@thermoline.com.au

Moving

Moving the drying oven:

- Ensure that the oven is rolled on an even and flat surface. Uneven surfaces can cause the oven to fall over.

IMPORTANT

Glassware drying ovens are 'Top Heavy'. Do not move the cabinet too quickly. (Fig 3 & 4)

Operating Environment

Oven Location

- Place the oven away from direct sunlight and heat sources (e.g., heaters).

- Ensure the room's ambient temperature does not exceed the oven's operational limits.

- Drying ovens should be stored inside at all times. Failure to adhere to this could cause significant drops in cabinet performance and damage to items stored inside.

Environmental Conditions

| Condition | Temperature | Humidity |

| Extreme Operating Environment | 10°C to 32°C (±2.0°C) | Up to 85% RH |

| Optimal Environment | 23°C (±2.0°C) | 50% RH (±5% RH) |

Bench Top Location

- Under no circumstances should ovens be stacked on top of each other (Fig. 2).

- Thermoline 150-litre ovens are equipped with removable castors for benchtop storage. To safely remove the castors, carefully tip the cabinet onto its back or side and unscrew the castors from the base (Fig. 3). This task requires two people—please seek assistance.

Electrical Connections

Glassware drying ovens require a 10amp, 230V, 50Hz power supply. The specific requirements for each model are shown in the table below:

| Model | Electrical Requirements |

|

TGD-80F TGD-150F TGD-250F |

10A/230V |

Electrical Conditions

- All glassware drying ovens include a 2.5m removable mains power lead with a three-pin plug and a right-angle female IEC plug.

- Ensure the product is reasonably distanced from the power supply to prevent strain on the lead.

- Each oven features a male IEC socket for power connection.

Important Notes

- Always use a dedicated outlet for the oven.

- Do not use power boards or extension cords to connect the oven.

Operating Environment Warnings

Operating Environment Warnings

- Do not store items on top of the cabinet as this will also affect ventilation!

- CAUTION: When installing multiple ovens in the same location, ensure they are positioned so that warm air exhausted from one cabinet is not drawn directly into another.

- Glassware drying ovens should be stored inside at all times. Failure to adhere to this could cause significant drops in cabinet performance and damage to items stored inside.

- Drying ovens are not suitable for use with flammable solvents! They are fitted with components that may be the source of ignition.

- The drying ovens are designed for large capacity drying, and hot moist air will be discharged.